or

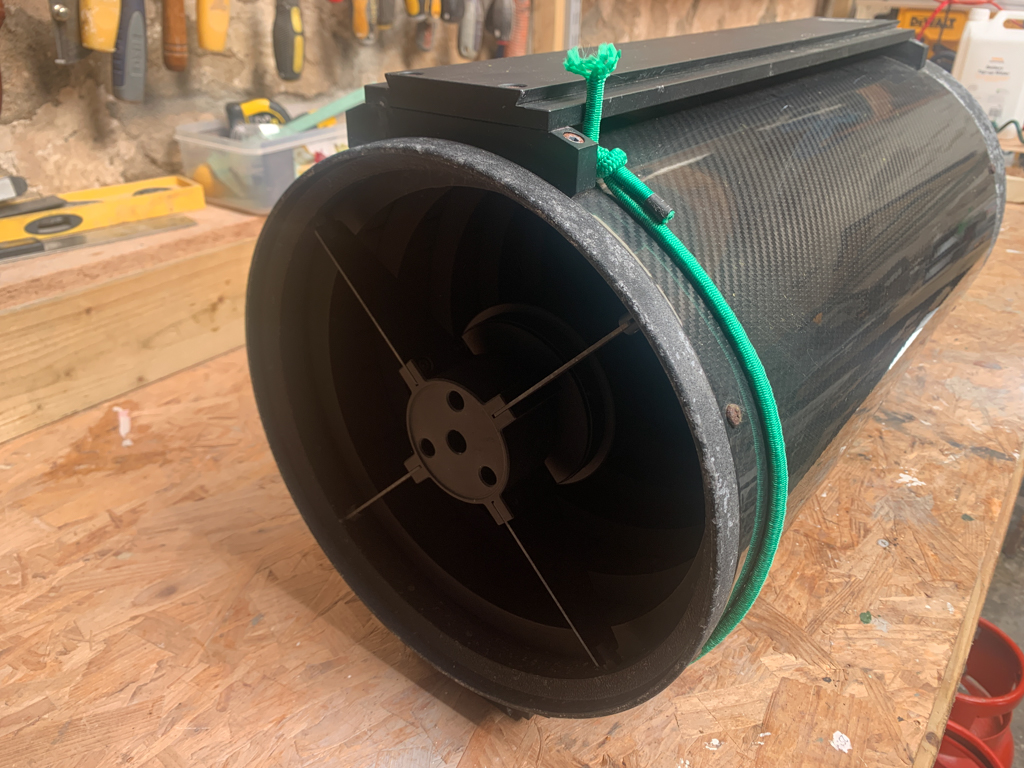

What 13 years in a drafty observatory does to your telescope.

The answer to this is not good. The two previous iterations of the my observatory were drafty. They were both designed to allow lots of air movement inside to discourage mould, but the problem was that we are on top of a moorland hull, rain and mist got driven inside it when it was windy. The gaps in the decking floor and the roof/side join being the two main culprits.

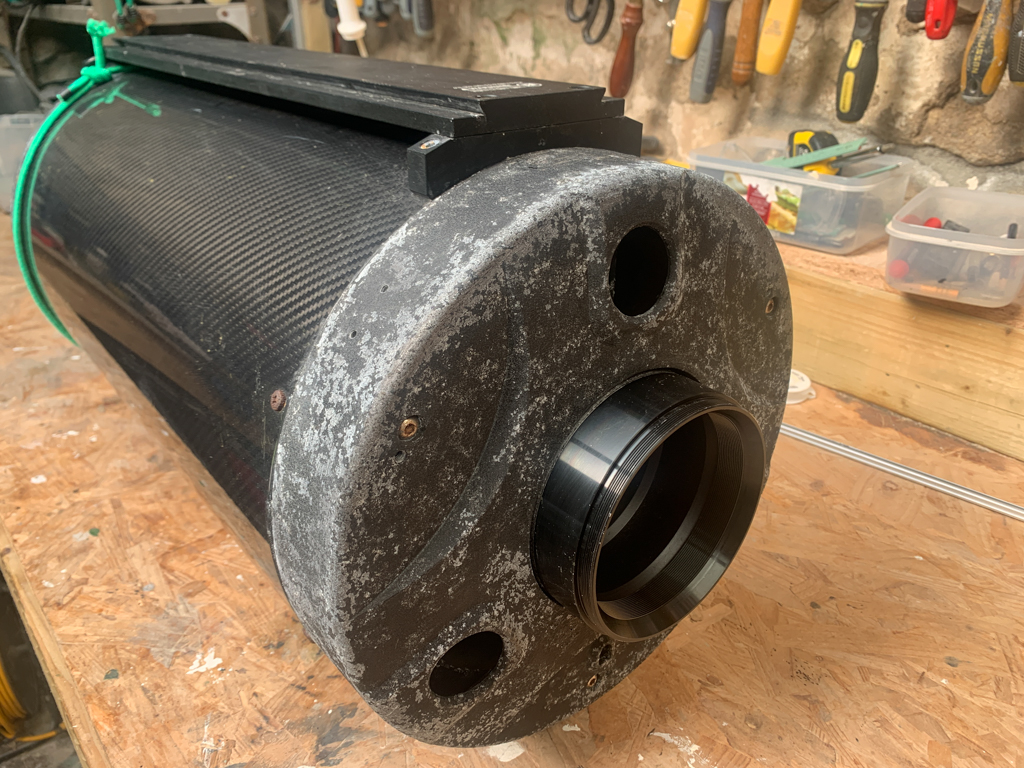

After 13 years of this, the aluminium castings were loosing their protective cover of paint and were corroding. The mirror had only ever had one clean about 5 years ago, so this Autumn I thought it could do with a complete stripdown and service.

This was bad enough. Image wise, all the crap on the mirror didn’t seem to affect my images much and all the corrosion on the external parts was just cosmetic. But it wasn’t till I stripped it down that the full horror of what laid inside was seen.

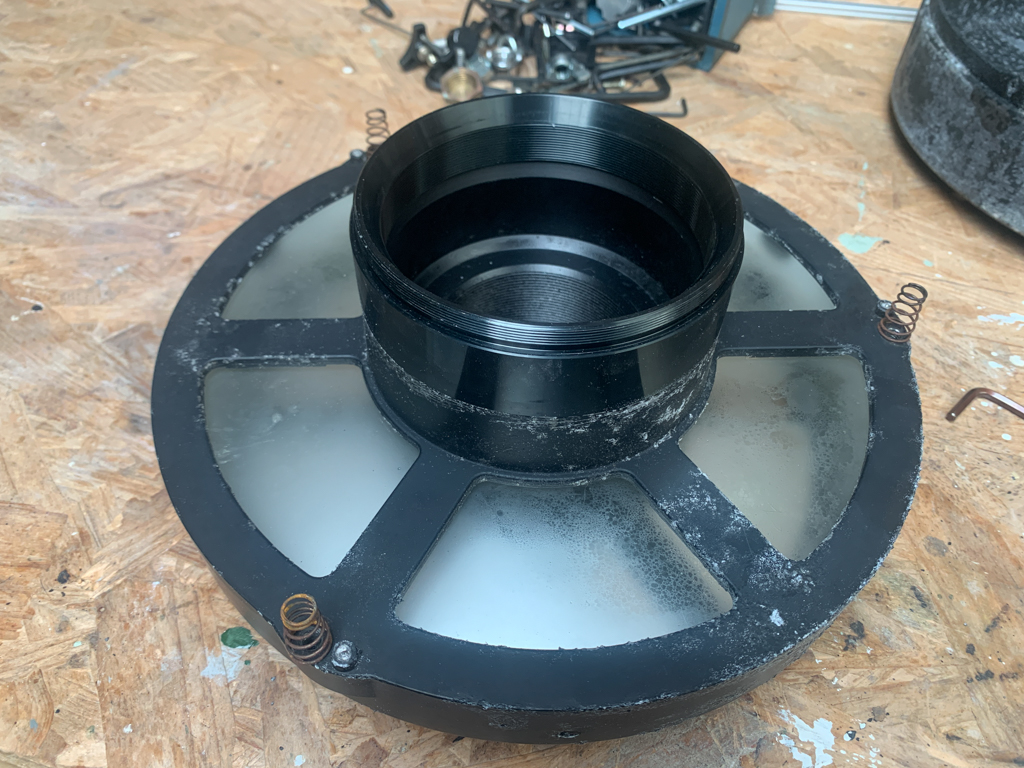

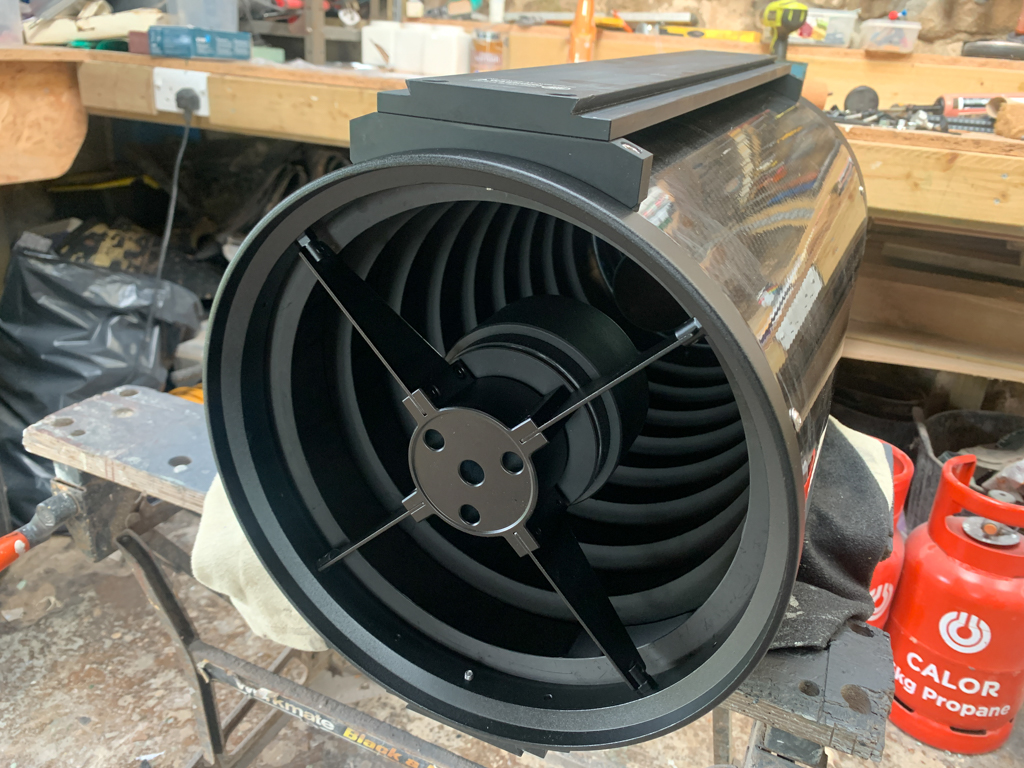

The corrosion on the mirror cell was bad. Even worse is that the light baffle that screws onto the adaptor was well seized and was a sod to get off. None of the screw threads anywhere on the scope had any anti seize compound on them, which always seems silly on aluminium.

The plan was to strip off the paint, and recoat. After a few coats of paint stripper it became clear that whatever this paint was, wasn’t being affected by the stripper.

In the end I decided to have all the parts bead blasted at a cost of about £60. With all the rotten anodising gone, I was left with completely uniform textured finish to which I could lay on 4 coats coats of aluminium primer.

This was followed by more than 6 coats of satin black acrylic paint. All these coats smoothed the finish left by the bead blasting and gave a very satisfactory sheen finish to all the parts.

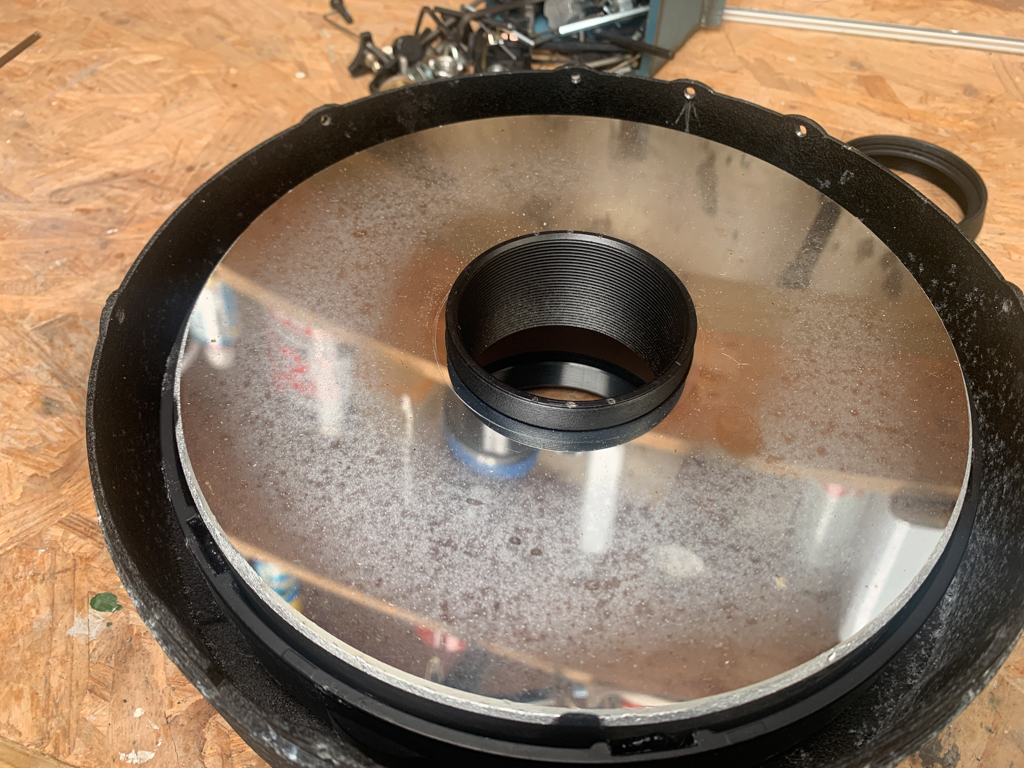

Both the mirrors were in better condition that the rest of the scope. There were a couple of dinks where coating had gone, but nothing was bad enough that warranted having to have them ‘resilvered’.

I added fresh cork mirror pads and then attached the mirror back in which is held in with Sikaflex.

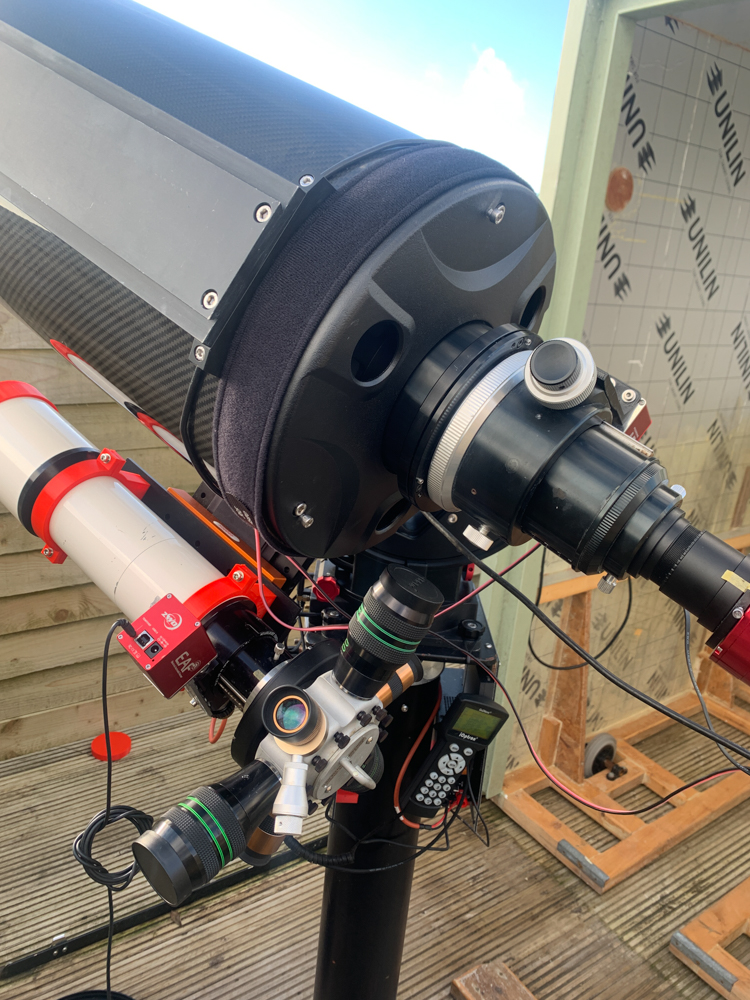

When rebuilding I replaced all the fastenings with marine grade stainless steel. Mixing stainless and aluminium is generally not a good idea, but I applied an anti seize compound to anywhere there was a thread connection. This should stop or at least dramatically reduce any galvanic corrosion and just as importantly stop the Ali to Ali connections from seizing.

All that was left to do was collimate the scope on the bench and mount it back on the mount for final collimation on the next clear night.

Having done all this work, I really need to get rid of that crappy focuser 🙁